|

| Before and After |

|

| Yellowed and Water Stained Back Panels |

I'm not sure why I chose the inside rear panels to begin the refurbishing work, but I had just pulled the top off, so they were easily accessible, and they stood out like a smoker's stained finger. The plastic was not only sun faded and water stained but also yellowed.

Looking back, the task was far more tedious than I originally thought it would be, but this is partly due to my own obsessiveness. I wanted the panels to be perfect, so I took my time. I not only primed and painted the panels, but I also sanded and painted all of the fasteners and screws. But in the end, it was worth it. My panels look brand new.

If you're planning on refurbishing the panels, I also suggest that you be patient and allot a chunk of time to do the project. The majority of time is spent in waiting for the paint to dry, and more importantly, to bond with the plastic.I waited 24hrs between coats, including primer.

|

| Needed Supplies |

Supplies:

Here's what I used:

- Flat head & Phillips head screwdrivers

- Steel Wire brush

- Brillow Brush

- Spray Paint

- 1 can of grey primer for plastic

- 1 can of grey paint for plastic

- 1 can of flat black for plastic

- 1 can of black gloss for metal

- Lemon Juice

- Baking Soda

- Glass jar

Removal:

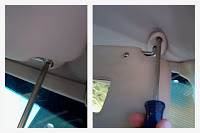

First I removed the panel doors from panels. Then, using a flat head screwdriver, I pushed it between the panel and the truck and gently pried the plastic fasteners loose. The key is to work gently as the plastic is 20 plus years old and can be brittle. Removing the fasteners is pretty straight forward. I had to loosen some of the fasteners to the middle panel in order to slide the rear panel loose, but the process is pretty straight forward. The wires for the light on the driver's side panel are easily disconnected.

|

| Removing Metal Tabs |

After I removed the panels, I also removed the metal tabs that give the bottom of the panels support.

I marked the location of the tabs on the back of the panel for ease when reassembling.

|

| Rear Light Fixture |

I also removed the light and hardware from the driver's side panel and unscrewed the knobs that lock the panel doors.

Finally, I rubber-banded plastic bags around the rear speakers to protect them from dirt or rain now that they were fully exposed.

Prepping:

I used the Brillo scrub pad pictured above and dish detergent and scrubbed the panels and plastic fasteners violently to remove the dirt and oil residue from years of driving without the top on. I washed and scrubbed each panel twice to make sure no dirt or oil residue was left behind to ensure the paint bonded to the plastic.

|

| Homemade Rust Removal |

The inside light fixture screws and the panel door hardware were in descent shape, but small oxidized spots were forming on them; the metal tabs on the bottom of the panel doors had already rusted some. I thought I might as well go ahead and refurbish all the metal parts to ward off future rusting.

To remove the old paint and rust, I used a home rust remover formula: lemon juice and baking soda. I mixed the two in a glass jar forming a wet paste (a little more watery than toothpaste) then threw in the hardware, mixed it well, and let it sit overnight. The paste removed much of the rust, but I also scrubbed each piece with a wire brush to remove particles and leftover paint. This was one of the more tedious aspects of the job, one that could easily be skipped to save time if the screws and nuts are in good condition.

Painting:

|

| Painted Metal Hardware |

I painted all the metal parts with rust resistant black gloss spray paint and set aside to let dry. This included the metal tabs at the base of the panels, the deck lamp hardware, and the screws and latches for the panel doors.

|

| Panel Door Latch |

|

|

| Un-Primed vs. Primed |

I began painting the plastic pieces with a layer of plastic primer and let them dry for 24hrs. I had a hard time choosing whether I wanted to paint with Dark Grey Gloss or Regular Grey paint. I added a layer of primer to the back of a portion of one panel and tested out the colors. It didn't do me any good. The Glossy dark grey was attractive, but the scratches and defects in the panels were more obvious than with the normal grey paint. I thought the glossy might be too much "bling" for the old truck, so I went with the standard grey.

|

| Panel Buttons Ready for Painting |

Using the perforated edge of a pizza box, I rigged a little holder to paint the plastic fasteners that hold the panels in place. The configuration of the cardboard holder allowed me to paint the underside of the buttons as well as the top without soaking my fingers in paint. The V shape of the design also set up nicely as the paint dried. I poked a nail through the cardboard on the far end and put the turn dial for the panels' trap doors on it for painting as well.

After the first coat of paint, I noticed some parts of the panel looked 'glossy' and other parts a little flat. Not sure why. Maybe they needed a second coat of primer, but since I had already given them a coat of paint, I decided just to give them a second coat, waiting a day between.

Deck Lamp:

|

| Deck lamp: taped, primed, and painted |

I spent far more time on the deck lamp than a normal person would or should. I painted the screws and nuts with rust resistant black paint, and I taped off and painted the metal plate of the switch on the backside of the light (lower right pic), both to prevent rusting. After taping, priming, and painting the lamp deck, I then taped off the entire light except the switch, sanded and primed it, and then finished it off with a nice coat of flat black paint (upper right pic). The switch turned out fantastic looking brand new. It was a bit of a tedious process, but the end results were well worth it. The only problem is that when I removed the lamp from the panel, the plastic light cover basically crumbled to pieces because it was so sun worn. I'm still on the hunt for a new light cover...

The Rust-Oleum paint can says that full adhesion to plastic takes 5-7 days, so I waited a full week before I reinstalled the panels. After painting the rear side panels, I knew they were looking good, but the full affect of how well they turned out didn't hit until I had put them back in the struck. The panels look amazing. The transformation is stunning.

|

| Finished Product! rear panel, driver's side |